The Differences between Casing & Tubing

"Casing" is an important term in oil and gas drilling projects. It is often used to describe the steel pipe used in the well-bore to support the well wall, isolate the formation, and protect the drilling safety.

What is casing?

Casing refers to steel pipes that are lowered sequentially into different strata as the well depth increases during the drilling process. Cement is used to secure the casing between the well-bore and the casing to ensure well-bore stability, prevent well-bore collapse, isolate oil, gas, and water layers, and prevent fluid cross-contamination.

The main functions of casing:

Supporting the well-bore wall and preventing collapse;

Preventing cross-flow and contamination of formation fluids (oil, water, and gas);

Withstanding formation and well-bore pressures;

Providing a path and foundation for subsequent production tubing.

Casing Classification (by Application)

Conductor Casing(20”): The shallowest casing, used to prevent surface collapse and divert flow.

Surface Casing(13⅜″): Isolates shallow aquifers and prevents contamination.

Intermediate Casing(9⅝″): Used in complex formations for pressure control and to prevent lost or blowouts.

Production Casing(7”): Reaches the oil and gas strata for long-term oil and gas production.

Liner(5½″): Installed at a specific depth within the previous casing to save costs.

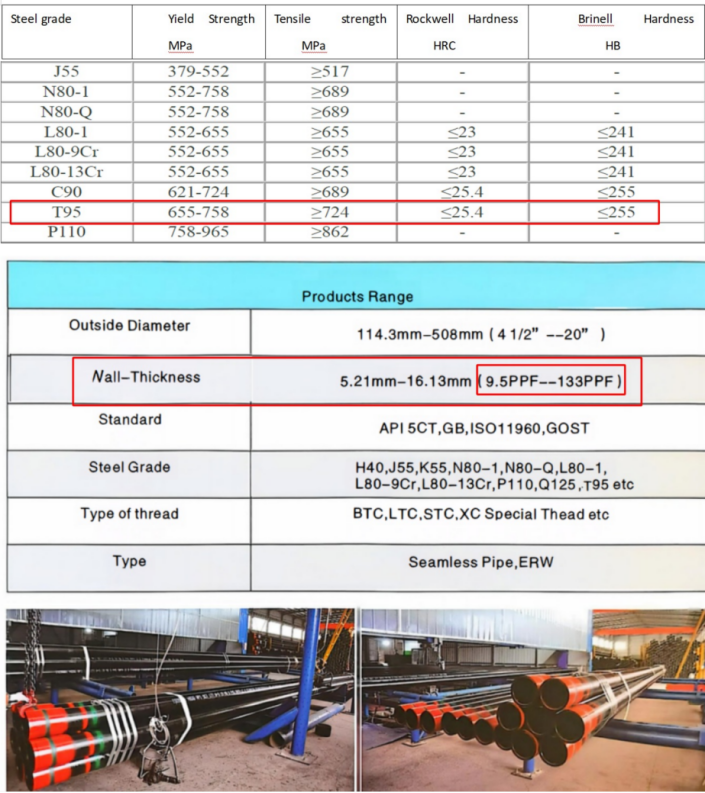

Common specifications of Casing

OD(mm) | DN(mm) | Commonly used layers |

20” | 508 | Conductor Casing |

13⅜″ | 340 | Surface Casing |

9⅝″ | 244 | Intermediate Casing |

7” | 178 | Production Casing |

5½″ | 139.7 | Liner |

After the casing is lowered, cement slurry is injected into the annulus between the casing and the well-bore wall. The casing is fixed and the inter-layer pressure is isolated through the "cementing" process, which is an important step to ensure the long-term reliability of the casing.

What is tubing?

Tubing refers to a small-diameter steel pipe installed inside casing. It is used to transport oil, gas, and water from underground wells to the surface during oil and gas production. Tubing is a critical channel in oil production systems.

Main Uses of Tubing

Oil and Gas Recovery: Transporting underground oil and gas to the surface through tubing;

Gas and Water Injection: Injecting gas, water, or chemicals into the well during tertiary oil recovery or flooding;

Tubing String Tool Operation: Used to suspend and operate down-hole tools such as packers and pump rods;

Well Work-over: Facilitates down-hole operations, including replacing equipment and addressing well conditions.

Tubing Structures:

Tubing string: A complete oil production channel connected by multiple tubes

Tubing hanger: Installed at the lower part of the Christmas tree and is used to suspend thetubing.

Tubing packer: Used to isolate between tubing and casing

Tubing pull-out (tubing pull): To lift the tubing string from the well during well work-over operations.

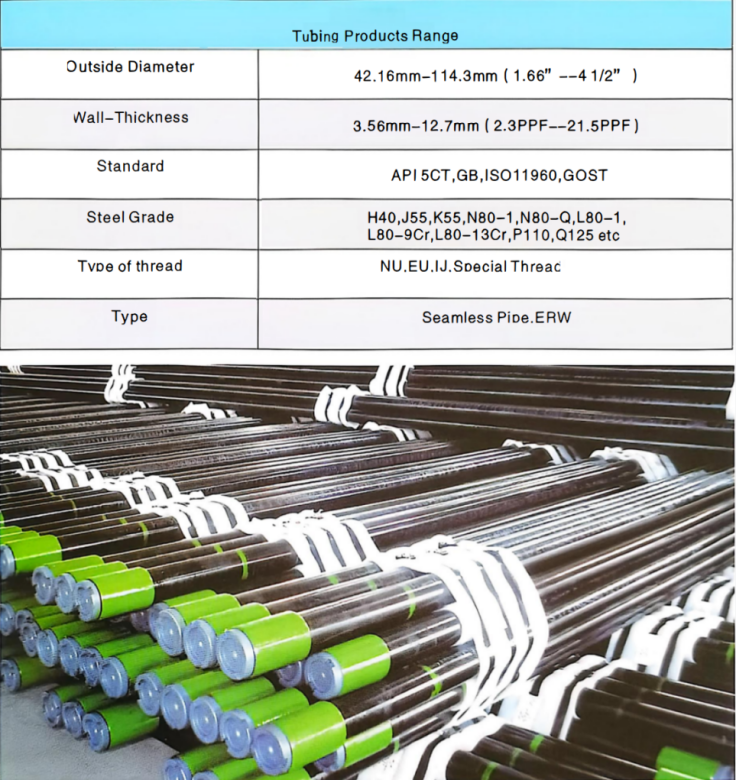

Common specifications of tubing

OD(in) | OD(mm) | Wall Thickness(mm) | Usages |

2⅜″ | 60.3mm | 4.19-6.45 | Commonly used in low-yield wells |

2⅞″ | 73.0mm | 5.49-8.38 | Mostly used specifications |

3½″ | 88.9mm | 5.49-10.36 | Medium and high-yield Wells |

4½″ | 114.3mm | 5.21-11.05 | Large-volume oil wells |

The differences between Casing & Tubing

Comparative Item | Tubing | Casing |

Function | Transport oil and gas to the surface | Support well wall and isolate formation |

Installation Location | Centrally installed in the casing, replaceable | Installed in the well wall and fixed with the well wall by cementing |

OD | Small (generally 2 3/8" to 4 1/2") | Large (generally 5" to 20") |

Whether to replace | Pull-out and replaceable | Generally not replaceable |