A Flanged Gate Valve

A flange gate valve is a common type of industrial pipeline valve, which combines the characteristics of flange connection and gate valve structure, and is mainly used to cut off the medium in the pipeline.

Structural Components

Valve body: The main pressure-bearing part, typically made of cast steel, stainless steel, ductile iron, and other materials.

Bonnet: Connects to the valve body to form a sealed cavity, typically also connected with flange bolts.

Gate(disc): The valve’s opening and closing member, available in shapes such as wedge-shaped and parallel.

Valve stem: Drives the gate up and down, and is available in either exposed stem(with exposed stem threads) or concealed stem(with threads embedded within the valve body).

Stuffing box and packing: To seal the valve stem to prevent leakage.

Flange port:Secures to the pipeline with bolts and gaskets for a reliable seal.

Working Principle

Opening the valve: Rotating the handwheel or electric actuator raises the valve stem, releasing the gate disc from the sealing surface and opening the pipeline.

Closing the valve: The valve stem descends, pressing the gate disc against the valve seat, shutting off the pipeline.

During the gate valve opening or closing process, the valve disc is perpendicular to the fluid flow direction, resulting in low resistance. It is suitable for full opening or closing and is not suitable for adjustment.

Features of flange gate valves

Advantages

Low fluid resistance,

Excellent sealing performance,

Simple structure and long service life,

Flange connection facilitates installation, disassembly and maintenance, making it suitable for large-diameter and high-pressure pipelines.

Disadvantages:

Long opening and closing times,

Occupies a large installation space,

Unsuitable for throttling and frequent opening and closing.

Common Applications

Oil & gas pipelines: Used for transporting crude oil and natural gas,

Chemical industry: Use stainless steel flanged gate valves for transporting corrosive media,

Power, metallurgy, and water treatment: Used for controlling high-temperature steam, water and other media.

Municipal engineering: Control the opening and closing of large diameter pipes in water supply networks.

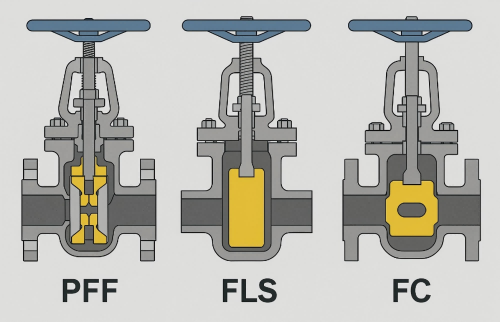

According to its structures, there are mainly three types of flange gate valve:

1, PFF(Parallel Face Flanged),Pressure Seal Flanged Gate Valve,

The gate plate is a double parallel gate plate, which is tightly sealed in the middle by a spring or medium pressure.

Used for: High-pressure wellhead device, blowout preventer system,

Oil and gas pipelines that require reliable sealing and frequent opening and closing.

2, FLS(Full-bore Slab Gate Valve)

After the valve is opened, the diameter of the channel and the pipe is consistent, and there is no flow resistance.

Used for: Valves for oil and gas pipelines;

Long-distance transmission systems that require uniform diameters and low flow resistance.

3, FC(Floating/Conduit Gate Valve)

The valve plate is generally of floating type or conduit type. When closed, it is sealed by the pressure of the medium pushing the valve plate.

Used for: Oil & gas wellhead equipment, Christmas trees, fracturing and high-pressure high-sand-content medium working conditions;

Situations where reliable cutting is required.