Well Completion Process

Well completion is a critical phase in the life cycle of an oil or gas well, marking the transition from drilling to production. This complex process encompasses a series of steps and technologies designed to prepare the wellbore for efficient oil & gas extraction. The following is an overview of the key phases in the well completion process.

1, Casing

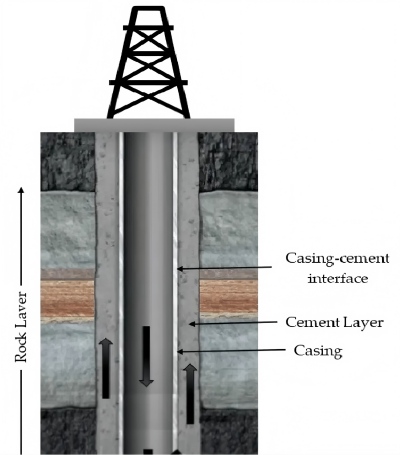

Casing is the first step in the oil well completion process, providing structural support and preventing fluid leakage within the well. Typically made of durable steel or alloy, casing is installed in sections and secured in place with cement. This protective barrier not only ensures the stability of the wellbore under geological pressure but also protects the surrounding formation from contamination. Casing, including the surface, intermediate, and production layers, contributes to the overall integrity of the well, providing a safe passage for the oil & gas production. Regular integrity testing and inspection are crucial to ensure the continued effectiveness of the casing in maintaining safe and efficient well production.

2, Cementing

Cementing is a crucial step in oil well completion, ensuring the integrity and stability of the wellbore. After casing is installed, cement is injected into the annular space between the casing and the wellbore. This cementing operation aims to hold the casing in place, provide structural support, and prevent fluid migration between different geological layers. As the cement hardens, it forms a robust barrier, enhancing wellbore stability and preventing environmental contamination. Cementing is a key step in oil well completion and makes a significant contribution to the overall success and safety of the well.

3, Open-hole completion technology

In oil well engineering, open-hole completion refers to the construction of an oil well without casing in a specific section of the wellbore. In this method, the reservoir rock itself acts as the structural support of the wellbore. Open-hole completion allows the wellbore to be in direct contact with the surrounding formation, thus enabling oil &gas to flow into the well more naturally. While this technology offers advantages such as cost-effectiveness and improved reservoir production efficiency, it requires careful planning and precise execution to address the challenges of well stability and fluid control under varying geological conditions.

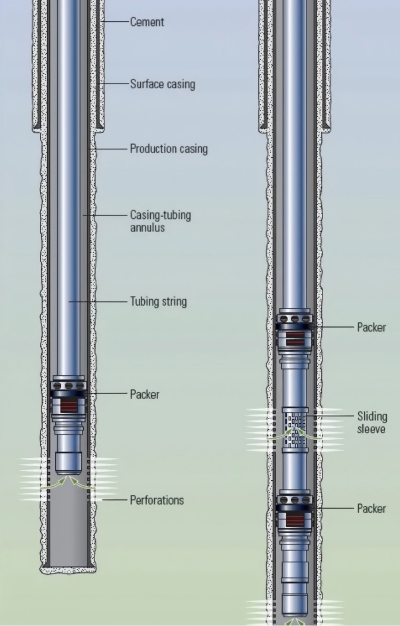

4, Perforation

Perforation refers to drilling holes in the casing of an oil well to establish a direct connection between the reservoir and and the wellbore. Using a specialized tool called a perforating gun, holes are carefully drilled into the casing, penetrating deep into the surrounding rock formations. This process allows fluids from the reservoir to flow smoothly into the wellbore, enabling the extraction of oil and natural gas. Perforation is a carefully planned procedure that ensures optimal connection between the well and the reservoir, thereby increasing well production and paving the way for successful oil & gas extraction.

5, Gravel packing

Gravel packing is a well completion technique used in oil & gas wells to improve their production efficiency and lifespan, especially for wells located in unconsolidated or loosely packed formations. In this process, a special mixture of sand and gravel(the gravel packing) is injected around the working casing around the wellbore. This forms a permeable barrier that helps prevent sand and formation particles from entering the well, thus ensuring more stable and efficient flow of oil & gas. Gravel packing plays a crucial role in addressing sand production issues, maintaining reservoir integrity, and optimizing overall well performance in complex geological environments.

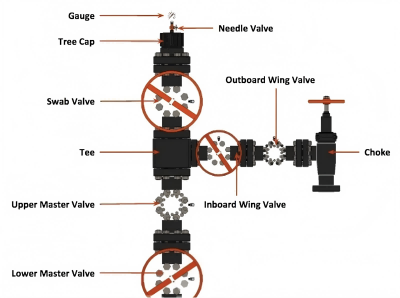

6, Christmas tree

The final step in well completion is installing the wellhead assembly on the surface. This assembly, often called Christmas tree, includes casing head, tubing head, enabling surface control of downhole conditions. Christmas tree are used in both onshore and offshore wells and come in dry and wet types. Dry Christmas tree are installed on the deck of a platform above the waterline and connected to the subsea well, wet Christmas tree is buried in the seabed and encased in a protective steel box. Well with multiple reservoir levels may use a dual-wing Christmas tree for separate completions. Modern completion techniques incorporate downhole sensors, or small wells, measure flow characteristics and optimize productivity.