Detailed Introduction of API Grade

API Material Grade

In the technical indicators of wellhead Christmas trees, we often encounter material grades. API divides material grades into seven grades, which are often seen on emergency shut-off valves, nozzle manifolds, desanders, heaters, and separators. This is what we often call the sulfur resistance grade.

AA: general use, material: carbon steel or low alloy steel

BB: general use, material: carbon steel or low alloy steel

CC: general use, material: stainless steel

DD: acid environment, material: carbon steel or low alloy steel

EE: acid environment, material: carbon steel or low alloy steel

FF: acid environment, material: stainless steel

HH: acid environment, material: corrosion-resistant alloy

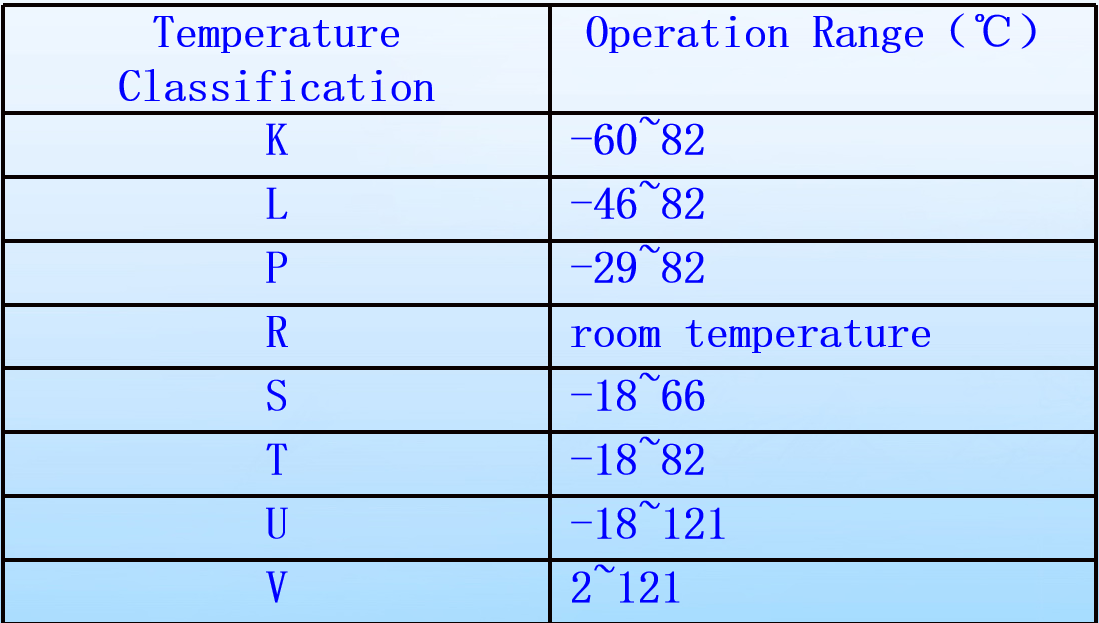

API Temperature Grade

Definition: In the technical indicators of the wellhead Christmas tree, the temperature grade API has strict requirements. Because the oil equipment manufacturing often refers to the API6A standard, the temperature grade symbol is often seen on the equipment nameplate.

Commonly used on nameplates for equipment such as wellhead Christmas trees, emergency shutoffs, nozzle manifolds, desanders, and separators.

For example: Temperature class P-U represents -29°C to 121°C.

API Product Specification Grade

API specifies five product specification levels with different technical requirements, namely PSL1, PSL2, PSL3, and PSL3G. API 6A 19th edition added PSL4, which is actually a variety of tests and records before and after the processing of raw materials and parts. The larger the number, the wider the scope of the inspection and record, and the higher the price. API 6A has clear regulations on which level to use in what environment.

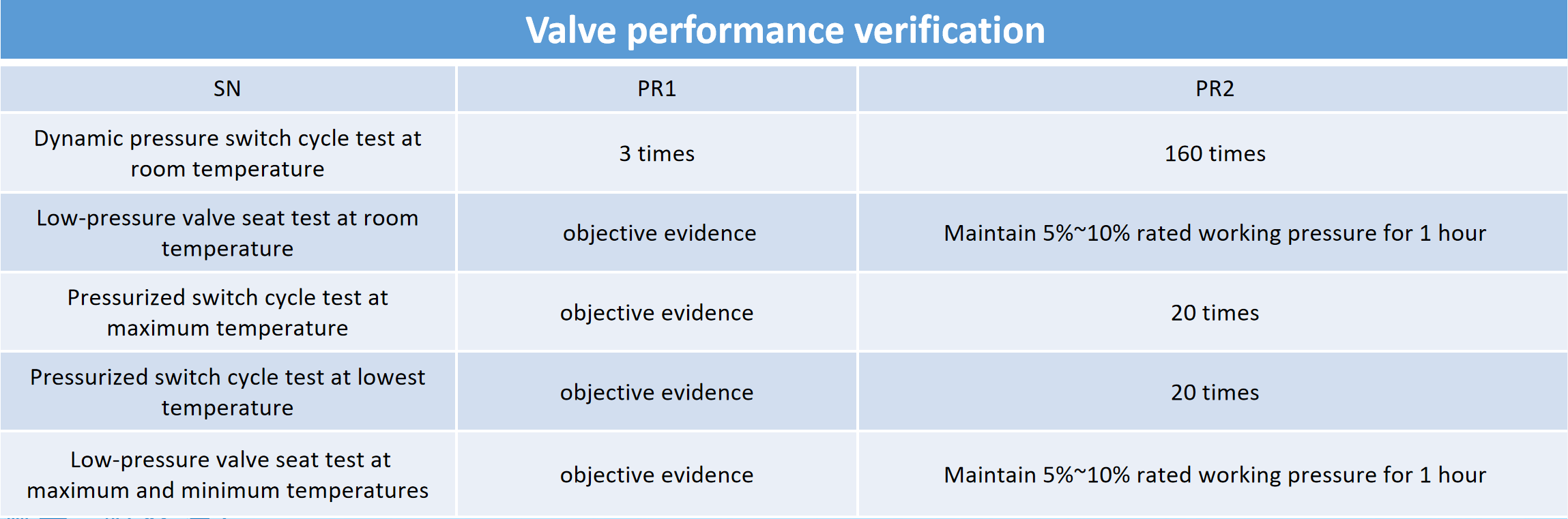

API Product Performance Levels PR1 & PR2

API product performance levels are divided into two levels, PR1 and PR2, which are the two levels of wellhead equipment and Christmas tree equipment. They mainly involve performance test requirements under load or switch operation cycles, high and low temperature and cyclic conditions. In particular, the PR2 performance qualification test has many test steps and harsh working conditions. It places very high demands on valve sealing and reliability, and the test is difficult to pass. The valves are first subjected to diameter testing and pressure testing (including valve body hydraulic test, valve seat hydraulic sealing test, valve body air pressure test, valve seat air pressure sealing test, and upper seal air pressure test) in accordance with API6A (ISO10423)/GB22513 standards. After passing the test, the PR2 performance test is carried out in accordance with the standard. The specific test key procedures are compared as follows (partially)