Extended Reach Wells(ERW)

1, What is an extended reach well?

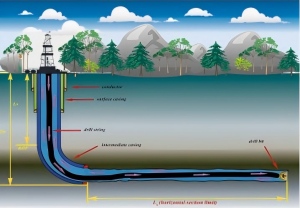

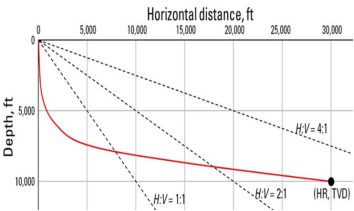

An extended reach well(ERW) is a well drilled with a very large horizontal displacement compared to its true vertical depth(TVD).

Extended reach drilling is a technology for drilling longer horizontal wells at a high inclination angle to reach underground oil/natural gas deposits further away from the drilling spot, instead of drilling wells vertically.

Currently, more and more wells in the world are drilled horizontally, browse inside of the reservoirs for greater contact with the hydrocarbon is a goal more frequently, these wells are built with conventional drilling systems, for example: mud engines and rotary steerable.

While it is true that one horizontal well is a project more complex than one conventional well, return internal rate justifies assuming the risk.

Typically: Horizontal displacement>2*TVD

Long laterals reaching several kilometers

ERWs allow access to reservoirs far away from the surface location.

2, Why ERWs are drilled?

-Reach offshore or environmentally sensitive areas from one pad

-Reduce number of surface locations

-Access remote or depleted compartments

-Maximize reservoir contact from a single well

ERWs are economic and environmental solutions

3, Key Characteristics of ERWs

-High inclination over long distances

-Tight torque and drag margins

-Complex wellbore geometry

-Requires advanced drilling and completion design

4, Major technical challenges

-Torque & drag

Long wellbores increase friction ---limits reach

-Hole cleaning

Cuttings transport become difficult at high inclinations

-Wellbore stability

Extended exposure time increases collapse risk

-Casing running & cementing

High friction and poor mud removal

5, Completion considerations

-Slim completions

-Advanced centralization

-ICD/AICD to balance inflow

-High-strength tubulars

Completion success is as critical as drilling success.