Connection Method of Hammer Union

Before connecting, clean the pipe joint of the hammer union and replace the sealing ring if needed.Put each part of the hammer union in correct location and tighten them together(facing the flat surface of the hammer union ear and rotate clockwise) Strike and tighten it with a hammer.

1, Personnel involved in the operation must wear protective goggles correctly.

2, When performing knocking and striking operations, irrelevant personnel should evacuate to a safe place.

3, When multiple people working together their positions should be reasonable and correct to make sure the operation will be safe and smooth.

4, Before operation, the tools used should be checked carefully to ensure that the connections are not loose and the tools are firm and reliable.

5, It is strictly prohibited to use non-specialized tools such as pipe wrenches and spanners instead of hammers for striking operations.

6, When open the well for gushing, use an explosion-proof hammer to strike the tubes.

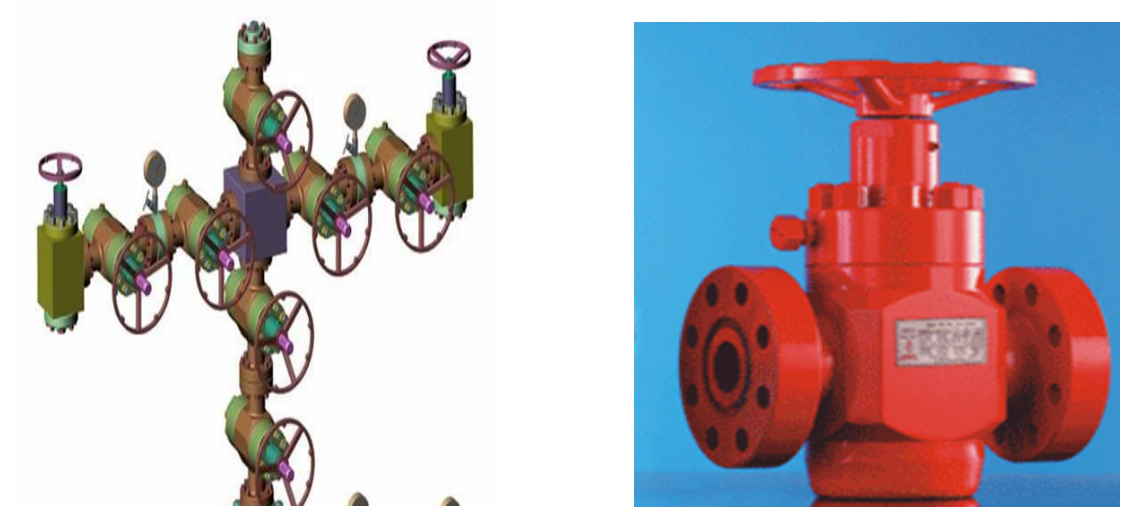

High pressure equipment such as oil Christmas trees and oil nozzle manifolds are mostly connected by flange connection. Compared with other connection methods, flange connection is tighter, the sealing is better and pressure resistance is higher.