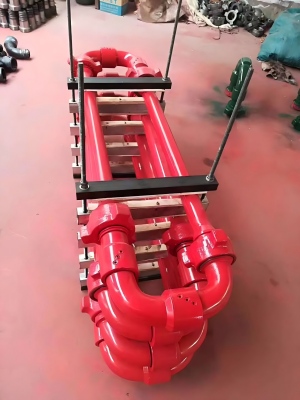

Choke Manifold

Introduction

-The choke manifold is a system of valves and chokes for controlling the flow and pressure from the well.

-Usually has two flow paths, one adjustable choke used primarily for cleaning-up the well, and facilities to install and change choke of fixed size for a more accurate flow control during main well flow periods.

-Each flow path has two closing gate valves which are used to direct the flow through either of the chokes and to provide isolation from pressure when changing the fixed choke.

-A dual isolation, double block and bleed valve arrangement is recommended for high pressure, sour gas and sand frac clean ups.

-The choke manifold, with a design featuring a fixed and adjustable choke, is a versatile piece of equipment.

-At both chokes, the size of the orifice that fluid flows through can be varied, allowing maximum control over fluid flow rate and pressure.

-In addition, the adjustable choke makes it possible to control flow pressure without stopping the well, further enhancing the flexibility of the system.

-The combination of a fixed and adjustable choke allows the choke manifold to achieve various flow rates(low & high) as needed to support well testing requirements and client specifications.

The choke manifold consist of:

-Four gate valves used to isolate the choke boxes on either side of the choke manifold.

-A fixed choke box to insert calibrated choke beans of different diameters, depending on the pressure and flow rate required.

-An adjustable choke to gain quick control of the well and to change fixed choke beans without interrupting the flow.

-Tapping points for measurement of the upstream and downstream pressures.

-Thermometer well inserted in the flow path allowing the fluid temperature to be monitored.

Functions

-The choke manifold is used during well testing to control the fluid from the well by reducing the flowing pressure and by achieving a constant flow rate before the fluid enters the processing equipment on the surface.

-The positive choke has a fixed diameter and the size of the orifice on the adjustable choke can be varied.

-In addition the adjustable choke allows fixed chokes to be switched out as needed without stopping the well, increasing the flexibility of the overall system.

-It allows wellhead pressure to be controlled, improving safety.

-It maintains a certain flow rate, as required for testing. A test can require different flow rates over several time periods, requiring the use of different choke sizes.

-It prevents formation sand from entering the well by limiting the flow rate. Limiting the flow rate reduces the speed of the fluid, which in turn, minimizes the amount of sand entering the well.

-It also prevents water and gas coning by the limiting the flow rate.

-It is also used to ensure that the flow is critical, meaning that the pressure fluctuations downstream of the choke manifold do not affect downhole pressure and flow rate of the well.

-When testing a well, the aim is to impose critical flow across the choke.

-When critical flow is achieved, changes in pressure and flow rate made downstream from the choke do not affect downhole pressure and flow rate.

Fixed choke

-On one side of the choke manifold, calibrated choke beans are used to control flow rate through the fixed choke box.

-Each bean is a specific diameter, usually in graduations of 1/64inch, and is screwed into the choke box.

-Choke bean is often used in the positive choke valve for controlling the flow.

Choke bean

-A positive choke has a fixed orifice size.

-Even though fixed chokes are available in a wide variety of sizes and types, the choke must be disassembled to change bean size.

-Depending on the type if equipment used, the size of the choke bean can be as large as 3 inchs.

Feature

-Choke bean size: 4/64”-192/64” increment with 1/64”.

-Choke bean material: tungsten carbide or ceramic.

-Medium: oil and gas, water, sand.

Adjustable choke

-Adjustable choke provides variable orifice sizes through some type of external adjustment device.

-Adjustable choke valves are often used in the oilfield when drilling, testing, or production.

-Adjustable choke valves have many sizes and pressure ratings used for oil field application.

Feature

-Manufactured and tested in accordance with API6A.

-Material: carbide alloy is embedded into stem needle of valve(stem tip) and tapered seat.

-Adjustment: flow adjustment is indicated on a measuring scale or graduated barrel.

-Max orifice: 1”-3”

Conclusion

-Different types of choke manifolds are available depending on the working pressures and the type of gate valves.

-Choke manifolds are generally available in 5k, 10k, 15k psi.

-The choke manifolds have four gate valves arranged in such a way that the flow can be directed through either the fixed or the adjustable choke. The valves are opened and closed by hand wheels.