Hydraulic fracturing is a stimulation technique used to create high-conductivity flow paths in low-permeability reservoirs(shale, tight sandstone, tight carbonate). High-pressure fluid is pumped down the wellbore to crack the rock and place proppant to keep the fractures open.

1, Why fracturing is needed?

Unconventional reservoirs typically have:

-Very low permeability(0.0001-0.1mD)

-Natural fractures that are insufficient to sustain flow.

-High capillary pressure preventing hydrocarbons from flowing to the well.

Fracturing artificially increases permeability by 10x-10000x through:

-Creating new fractures

-Extending existing ones

-Placing stable proppant channels

2, Core components of a Frac job

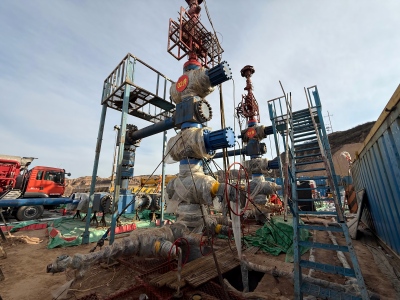

Surface equipment

-Frac pumps(diesel or electric e-frac)-generate 5000-15000psi

-Blender-mixes sand and chemicals into fluid

-Hydration unit-prepares gel/FR fluid

-Sand kings/silos-proppant storage

-Data van-real-time monitoring

-Fracturing manifold/zipper manifold-routing high-pressure lines

-Chemical additive units

Downhole components

-Frac string/plug-and-perf guns/CT string

-Bridge plugs or ball-drop sleeves

-Packer assembly

-Frac ports & perforations

3, Fluids systems

Slickwater(shale frac)

-Water+friction reducer

-Low viscosity

-High pump rate(60-100bpm)

-Advantages: low cost, long fractures, good for shale

Crosslinked gel(conventional tight sandstone)

-Guar gel+borate/crosslinker

-High viscosity

-Carries large proppant volumes

-Used in conventional tight gas, deep high-pressure reservoirs

Hybrid systems

-Start with slickwater for fracture initiation

-Switch to gel for proppant transport

4, Proppant types

White sand(cheap, shallow wells)

Brown sand

Resin-coated sand

Ceramic proppant(high strength, deep>8000-12000psi closure)

5, Frac job workflow(stage by stage)

-Rig up equipment

-Pressure test iron

-Perforate (plug and perf) or open sleeve(ball-drop)

-Breakdown

-Pad stage(no proppant)-create initial fracture volume

-Proppant stages-increasing concentration

-Flush stage-clear tubing

-shut-in

-Move to next stage(zipper frac for multi-well pads)